In many cases, the manufacturers will opt for using CNC routing. Naturally, we can see that this is not the only option they have in front of them. There are a lot of cases that have proved themselves capable of handling the manufacturing of many custom-built parts.

Nevertheless, CNC routers have established themselves as the most effective of them all. It is easy to see that they weren’t the most widespread of them all until recently. There are many reasons for this. The main one is the costs of purchasing and maintaining this sort of machinery.

That’s why many opted for milling machines or some other devices. Nowadays, the accessibility and reduced costs of CNC router machines. If you want to have an insight look into these, you should visit plasticmold.net. Finding the right brand might just be the game-changer in this case.

Understanding all the essential factors about this concept before purchasing these is an absolute must. That’s why we would like to talk about a couple of elements you need to be aware of before you decide to invest in CNC router machines. Without further ado, let’s take a look at some of these.

Table of Contents

1. The Type of Router

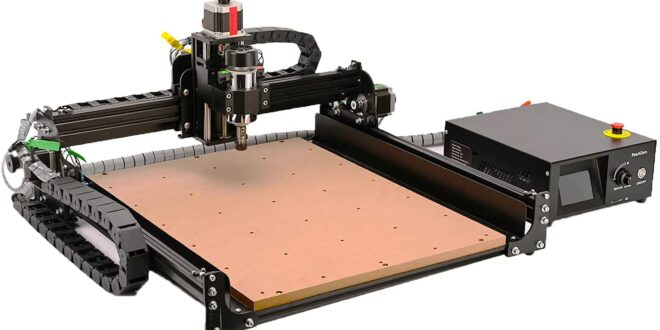

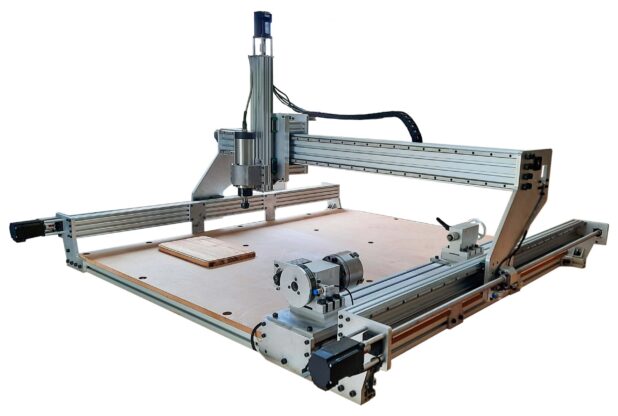

The first thing you need to be aware of is that not every CNC router you see will meet the requirements needed in your case. Thankfully, finding quite a lot about these varieties between similar machines comes easy, just by taking a look at their names. Plus, there are not a lot of them to take a look at.

One of the finest examples you can see is a CNC wood router. You will certainly agree with the fact that this shows that the device we are talking about is completely different from a 3D printer. Furthermore, you can check the categorizations like mini, light, or heavy. Be sure to consider these when buying.

2. Capability

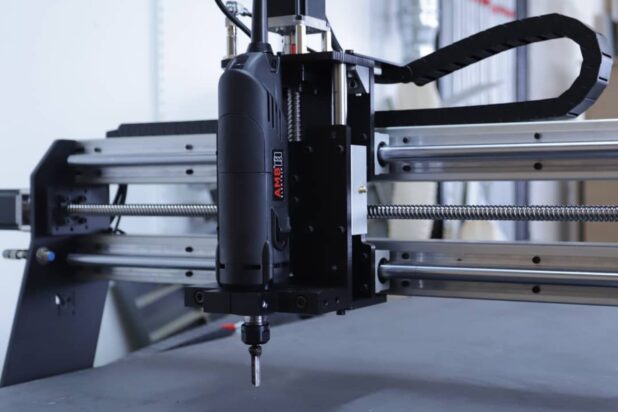

It’s quite obvious that knowing what you need these machines for will be a vital factor in your decision. Still, it is important to understand the situation in much greater detail. Why you should be aware of these little things? Well, the machines are calibrated according to your needs, it is as simple as that.

Things you need to take into consideration are safety, maintenance, and speed. Also, it is important to know what materials you will work with. Not to mention that working with composite materials, like aluminum, requires a special sort of calibration for efficient performance.

3. Performance

Without any doubt, the performance of the device you are about to purchase is something that will be a significant influence when deciding on whether to buy. For you to understand the information placed in front of you, reading specialized literature would be something you should miss on out.

In case you don’t have the time to go through these documents at the moment, you can always hire a professional who can tell you a lot about this topic. Thankfully, you can find numerous credible experts out there who would gladly provide you with the crucial information on whatever you need to know.

4. Customer Service

Since you will purchase a CNC router from the manufacturer, having some sort of help in the time of need would be a bonus for you, right? Well, that’s why you should double-check whether the company you are interested in contacting can provide you with responsive customer service.

Sadly, you will see that not many of these will provide you with this chance. At the same time, the most prominent ones will present you with this option. You can be certain that this is one of these little details that truly make a company stand out from its competitors.

5. Cycle Time

One of the biggest problems people face these days is working within certain deadlines. Sure, having these is an essential factor in calculating the performance. Still, a vast majority of them are unreasonable. For this reason, they are often broken, no matter what industry you are in.

If you experience something like this quite often, you will be happy to hear that the most advanced CNC routers have a great cycle time and schedule. Meaning, all the processes that are done over a certain period will be carefully calculated before the process starts. So, you can always meet all the deadlines.

6. Your Budget

Next, it is crucial to come up with a budget. It is obvious that you should know how much money you can invest into these. Sure, the prices of these are much lower than they were until a decade ago. Still, that doesn’t mean that they are low enough for those who are on a tight budget.

When we talk about exact prices, you will see that talking about them is practically impossible. The price range goes between $3,000 and $200,000. The reason is quite simple, more complex devices come with a wide array of different features that make them much more efficient in cases you need them to be.

7. Return on Investment

Last but not least, we feel it is important to talk about the end goal of any investment, return on investment, or ROI. Calculating this percentage is not always easy because of many elements that need to be taken into consideration. When we say elements, we are talking about costs.

By purchasing a device that can remove a significant chunk of the costs in no time, it becomes obvious that you will have more ROI. CNC routers have proven themselves as machines that can automate a lot of processes that required much more time and work time.

The Conclusion

Knowing what sort of CNC routers you will need for your business is not always easy. People who are new to the whole concept will not know where to look. Here, you can see all the main factors you need to pay attention to when purchasing these devices. We have no doubt you will find them useful.

World Magazine 2024

World Magazine 2024