In the plastic and metal industry, it is very important to use quality materials, even for the smallest part of a project. Proper and safe operation of all components is crucial here. The reason to do so is necessary to examine the materials to select the best performance.

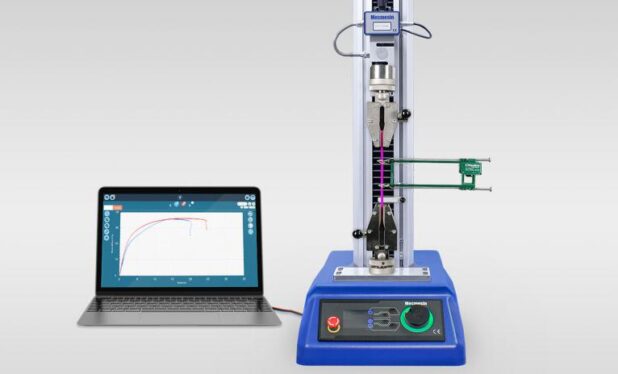

This is where Tensile Testing Machines come into play. Their main purpose is to examine and measure the effect that force leaves on a certain material or one complete component. The strength of the adhesive or fastener for certain materials can be tested in the same way. Tensile Testing Machines can test not only resistance to pressure but also resistance to puncture, bending, cyclic testing, and the like. That is why these machines are most often called universal Tensile Testing Machines. Different industries conduct different research depending on the project being worked on and therefore use different Tensile Testing Machines.

In any case, this is the perfect machine with which you can be sure that your product is of high quality. In addition to different types of tensioning machines, according to the needs of the manufacturer, some accessories and fittings can be adapted to different materials. As much as the machine is modern, the testing must be conducted by a professionally trained person with subordinate standards. In this guide, we will introduce you to a few things you may not have known about clamping machines.

Table of Contents

1. Hydraulic type Tensile Testing Machines

As the name suggests, this type of Tensile Testing machine is powered by a hydraulic cylinder. it can be moved up or down and thus the main or desired function of the machine is achieved. With the help of a motor on an oil pump, mechanical energy is converted into pressure energy. The hydraulic valve is the one responsible for the direction and pressure of the machine. The tightening force also depends on the oil source.

A machine of this type can provide much higher tensile strength. It can reach a load of up to 30T. It is most often applied to serious metallic materials. Thus, with the help of hydraulic Tensile Testing Machines, the quality of construction materials, bridge bearings, composite materials, and many others can be tested. However, the disadvantages of this type are poor hygiene of the machine and rather poor control accuracy. Energy consumption is huge, especially due to the need for additional, water or air cooling of the hydraulic oil source.

2. Mechanical Tensile Testing Machines

This type of machine is a rotation of the spiral screw of the motor. Its rotation moves the machine up and down and in this way; the traction of the load is achieved. You can visit this website for more detail about this type of bow:

This type of Tensile Testing machine will allow you to test peeling, splitting, bending, and more, and its greatest virtue is high precision work and a period of control over the entire process. It is most often used in the testing of rubber, textiles, plastics, wires, rods, and similar materials. This machine is very good for maintenance and easy to use. Its servo-motor drive enables higher energy efficiency. It is stable and reliable. It also allows control of test speed.

3. They can be either with a pointer or with a digital display

The traditional type of Tensile Testing Machines is the one with a pointer. It is clear to you that its sales, and therefore production, have been suppressed lately by the more modern one with a digital display. Although Tensile Testing Machines with a pointer is not sufficiently accurate and accurate, there is still a demand for them due to their low cost.

In contrast, Tensile Testing Machines with digital displays display accurate results on an LCD screen.

4. How the value of force is measured

The value of the force under test is measured using measuring cells, the most common of which is the load cell, ie the force measuring sensor. There are also amplifiers and systems for processing the obtained data.

Force sensors work by converting a certain mechanical force into electrical output. There is a huge number of sensors of different types, all depending on the purpose and use. The output signal that directly measures the force is quite weak. It is usually only a few millivolts. Therefore, it is necessary to use an amplifier. The signal voltage can be increased up to 10B with the use of amplifiers. However, the signal we get this way is analogous. This is where the multiplex switch enters the scene, which transforms the analog signal into a digital one. The higher the quality of the sensor, the more accurate the values will be.

5. What is the control system of Tensile Testing Machines?

This part of the machine is in charge of controlling the operation of the Tensile Testing Machines computer system. Control can take place via the console. It shows the test parameters and their status. More recently, these machines have been connected to the computer. In this way, additional controls of various functions are enabled. Also, it is possible to process data, analyze them and even print the obtained results.

6. What to focus on when choosing Tensile Testing Machines

There are many Tensile Testing Machines on the market. Different prices, different quality. The question is: what should you pay attention to when choosing Tensile Testing Machines. In the first place, look for parameters that suit your business. Define which types of titration you need and based on these specifications choose the type of machine you need.

Take care of the manufacturer you choose. There are a large number of manufacturers on the market who cannot guarantee you high quality but can offer a low price. However, we recommend that you choose the proven ones, with a long tradition and a recognizable name.

If you need the speed of tightening or some other factor, focus on the fact that your choice depends on these special performances.

Another, no less important item is spare parts. Find out how easy or difficult it is to find original spare parts for a machine that seems ideal to you. You know nothing, so even this machine doesn’t have an eternal shelf life. Therefore, provide yourself with this information as well.

We hope our guide has helped you learn more about Tensile Testing Machines. If you are looking for one like this, you must be familiar with the way it works to make the right choice.

World Magazine 2024

World Magazine 2024