The process of manufacturing a printed circuit board consists of many steps that cannot be avoided, and there are also those things that you can choose to implement or not in your production. One of the most talked-about steps is prototyping, and some people choose to do it while others want to skip it. If you are not sure if you should add this step to your assembly, you should continue reading. Here, we are going to list some of the most important reasons to prototype your circuit board first before manufacturing.

Table of Contents

1. You will make sure that there won’t be any issues

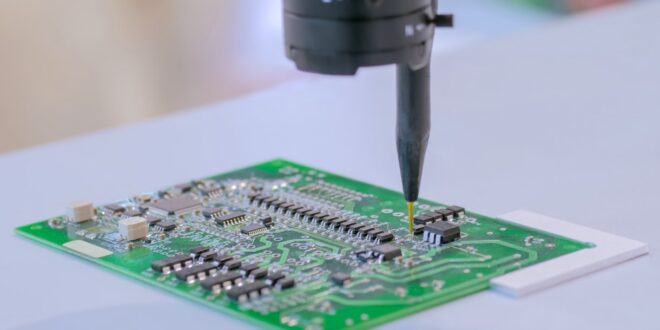

The first reason why you should choose to prototype your boards before you send them to get manufactured is to make sure that there are not going to be any unpleasant surprises. Sometimes there is going to be a small issue that can easily lead to overheating and it can cause permanent damage to the board after just a few minutes of working. In other cases, the soldering may be faulty and the components may not want to stick together. All these issues can be easily avoided as long as you do proper testing on a prototype instead of doing it on the board itself.

2. You will better understand the concept

When we create and plan the design of the units, we only see that in 2D and we just use different software and platforms on our devices. We understand what is going to happen and we have an idea of how the finished product is going to look, but we can never be too sure.

When you choose to make a prototype you will have the design in your hands, and you will see what it looks like from all sides. You can understand how it is going to look and function, and you will also be able to notice if there are going to be any potential issues before it starts manufacturing.

3. You will be able to make changes

Not all designs are perfect, and sometimes we just want to change one small thing that may not affect the way that the board works, but it is definitely going to affect how it looks or how it sits in the devices where it needs to be placed.

When we have a prototype, we are able to make as many changes as we want without affecting the costs or the overall manufacturing process. We can see if we like the smallest details and if we are okay with the overall look of the board. We can change the concept if we want, or we can just make a plan on how to improve future designs.

4. You will know how to plan your budget

Our budgets are going to make the biggest difference, and if we choose to start manufacturing, learn that there is an issue with the board, and go back to the basics just to change one simple thing can cost us a lot of time and money. We all work with limited budgets and if we don’t use a prototype, we can end up paying way too much and end up getting too little.

As you can view here, the prototyping costs are not the same as the manufacturing costs, and you can save a lot of money in the long run if you choose to do all the testing and all the changes before the official production process begins. Know that it is far easier to change your mind when you don’t have to commit to the design than to risk wasting both time and money.

5. The testing will take less time

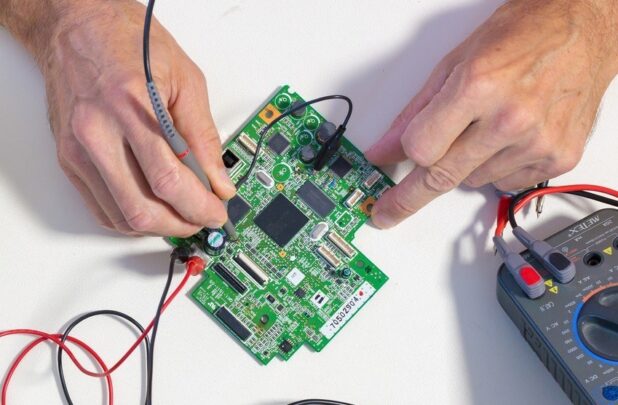

Keep in mind that prototyping and testing are not the same and just because you can test on the actual product does not mean that you should just do it. Testing on a prototype is going to be easier and you can avoid problems.

Note that this testing process is also going to be much faster and you can get rid of most of the potential issues in this phase. This does not guarantee that you are not going to come across a problem or two when you test the actual board, but it will definitely make things far easier for you down the line.

6. Fewer wasted units

We are all aware that there is always waste in the production process. We all make mistakes, the equipment we use sometimes is going to produce false goods, and we will decide to make changes at the last possible moment. Sometimes there is going to be an issue with the board itself, and that would mean that everything we have created before is just going to go in the trash.

When you choose to opt for prototypes, there are going to be fewer wasted units, and having 10 pieces that you tested on, made changes, and ended up throwing away is far better than having hundreds of them or even thousands. Keep in mind at sometimes you may notice the mistake when it is too late and you may end up having one thousand PCBs that are good for nothing but the trash.

When you go with prototypes, yes, there are going to be many changes, you will need to print the same prototype over and over again, and you are more likely to make changes to the design, but ultimately, you will not waste near as much product, time, or money when compared to what could happen if you didn’t utilize this option.

As you can see there are many reasons why you should prototype first and keep in mind that in this list, we barely just stretched the surface. Know that once you realize how much you need this step it may already be too late, and you may have spent thousands of dollars on a design that just does not work. Save yourself a lot of time and resources and know that this part of the process is one of the most important ones. With it, you can perfect the design, you can test out the software and the components, and can make changes on the go without affecting the brand.

World Magazine 2024

World Magazine 2024