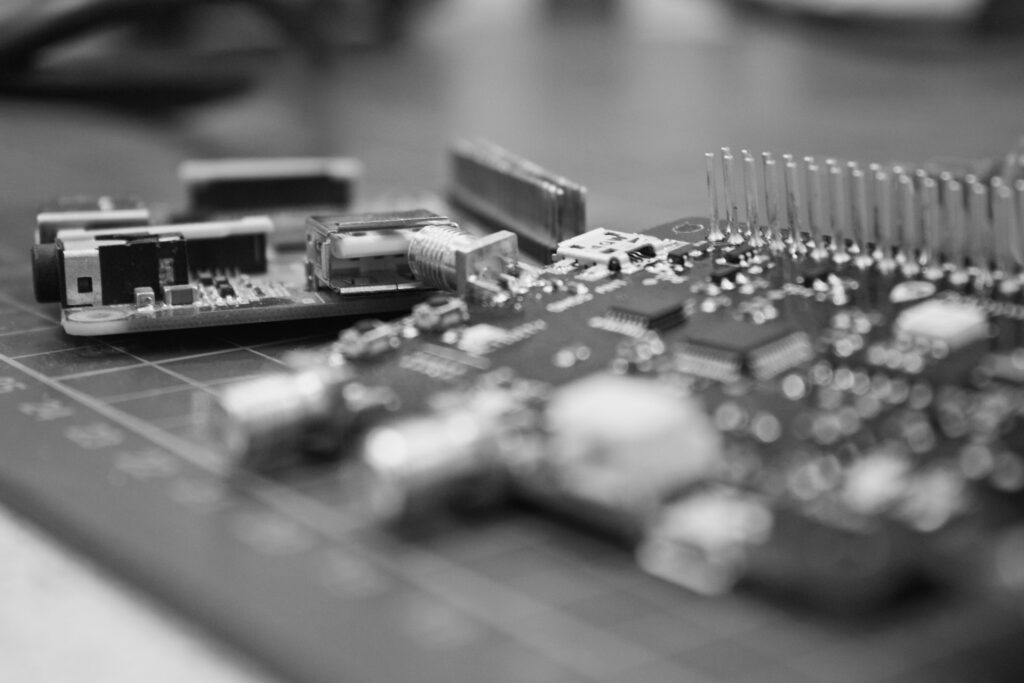

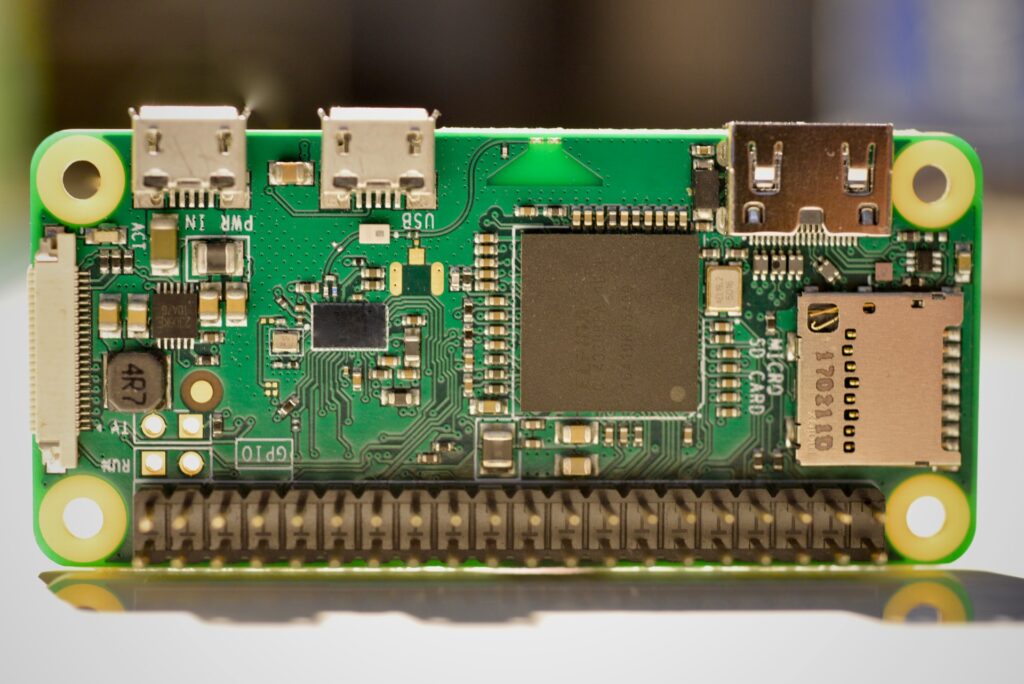

Whenever working in an industry as important as PCB, the mistakes you make can be very costly. But that doesn’t mean that mistakes don’t happen.

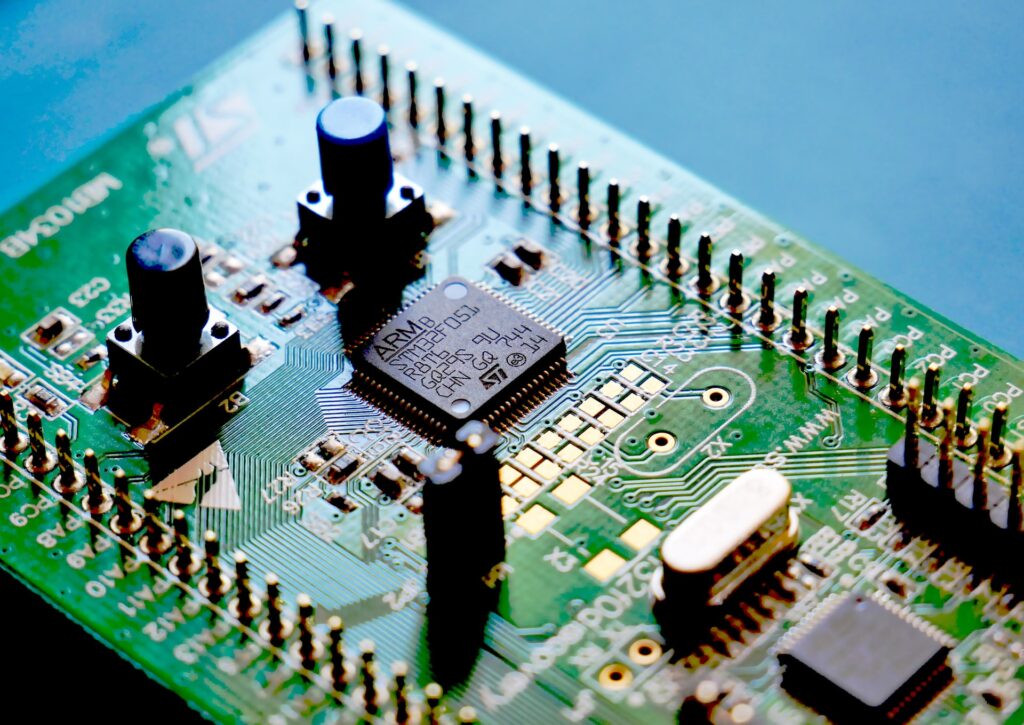

PCB stands for printed circuit boards, and they’re a vital component of everyday machines and tools.

Even if you’re new in the industry, it’s important to avoid making the following 8 mistakes in designing. With all that said, let’s start.

Table of Contents

1. Incorrect Landing Patterns

The first and most common design mistake to avoid making as a beginner is making an incorrect landing pattern.

The landing pattern is a vital component of the design process. With it being so important, making a mistake by even a millimeter can render the circuit board useless.

The easiest way to avoid making this mistake is to either train yourself in making the landing pattern or use libraries to do so.

Every PCV manufacturer has access to libraries of patterns and schematic tools that can be easily imported as opposed to manually drawn.

If you have to do it manually, spend the necessary time researching the pattern to draw it correctly.

2. Messing Up the Wireless Antenna Layout

If a particular PCB needs to go with a wireless antenna layout, then you need to make sure to get it right. A lot of components are needed for the wireless antenna to operate as it should.

The microstrip that connects the antenna and the transceiver is the most vital part. Without a proper one, the wireless antenna will not work.

The microstrip needs proper alignment and you can make sure to get it right by using a microstrip calculator. If you misalign this component, the wireless antenna will have a hard time reaching maximum power transfer.

PCBs with wireless antennas are very difficult to make, so spend the time researching the proper way to do them.

3. Incorrectly Placing Capacitors

Capacitors are equally vital components of circuit boards. And these components need a stable voltage source to work. But the main issue here is the fact that you can render the capacitors nonoperational if you don’t properly place them.

Namely, capacitors need to be as close to the voltage source as possible. And the power line needs to go to the capacitor before it goes to the pin, the part that brings voltage to the capacitor.

Because of this, correct placement is vital for the pin to connect with the capacitor and the power line. If you don’t do it correctly, you will never achieve optimization stability and get a false response in the process.

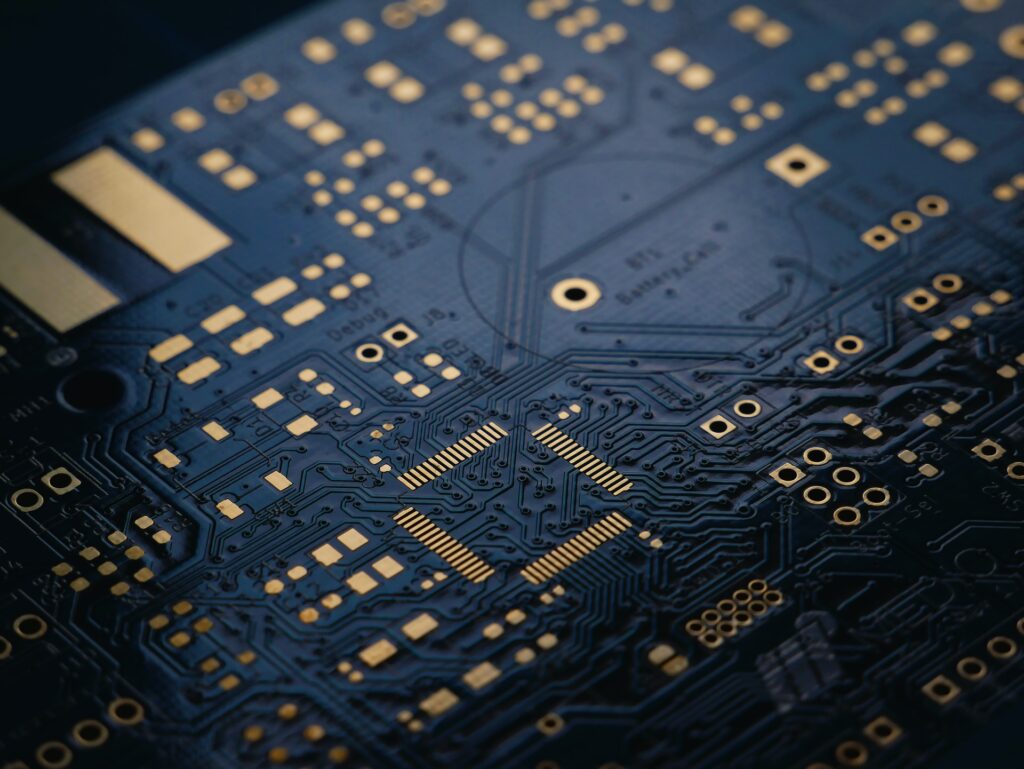

4. Insufficient Width for Power Traces

Each PCB trace needs sufficient width so that the optimal mA flows through it. If let’s say, the PCB trace has 500mA flowing through it, then you’ll need to design the trace somewhat bigger.

To know exactly how much, you’ll need to take into account two things. The first is knowing whether the trace is located on an internal or external layer. The second is the thickness and this depends on the amount of copper used. Copper weights differently and you’ve got some options when it comes to the thickness of the trace.

You can choose between 0.5oz/sq.ft or 2.5. If you need to accurately figure out the trace width, there are plenty of tools that can help with that. But what we suggest is to always go with a professional PCB manufacturing company that has access to professional PCB design software. For more information, check this out.

5. Over-complicating Things

Design is subjective but not in this industry. Making things complicated will only make them worse. This is the easiest way for beginners to make mistakes in the industry.

The design of the circuit board can directly impact the circuit board. And while beginners might think they know what they’re doing, that isn’t always the case.

Instead of complicating the design, you will need to think about whether or not the design is effective. Not everything will work the same way as you might think, so actually putting some thought into it will do you more good than harm.

As a general rule of thumb and a mistake to always avoid, never complicate the design process.

6. Don’t Skip the Schematics

The schematic is an important part of the design process. This isn’t only the case in the PCB industry, but in any industry that has design involved.

Schematics help us put pen to paper. And it is the easiest way to know whether or not something is wrong with your design. The easiest way for beginners to make mistakes is to skip this part.

Drawing up a schematic can really tell you whether or not there’s something wrong with the PCB design. So always prioritize it before actually making the PCB.

7. Avoiding Failures

It’s not uncommon for manufacturing failures to render a circuit board useless. These failures are mostly due to undissolved copper or improper connecting of parts.

And make no mistake about it, these failures will render all previous work obsolete. Failures are the easiest way to cause a short circuit. This can result in the complete destruction of the circuit board and any other electronic that connects to it.

Failures are more commonly known as slithers in the industry. And the easiest way to prevent slithers is to follow the design instructions to the letter.

8. Not Doing Your Research

Ultimately, mistakes can and will happen if you’re a beginner. The question is whether or not you’re ready to move past them and leave them behind.

The industry is very delicate and everything impacts whether or not you’ll make a mistake. So instead of thinking about it, why not do your research on how to prevent making them?

We also mentioned previously that you should have access to plenty of libraries on components and parts. Making sure to connect all the dots as the manual says will prevent a mistake from happening.

So don’t dwell too much on it and instead get to researching.

World Magazine 2024

World Magazine 2024